The Benefits of Partnering With a Top-Rated PCB Prototype Service Provider

PCB Prototype Services: A Burst of Innovation and Complexity

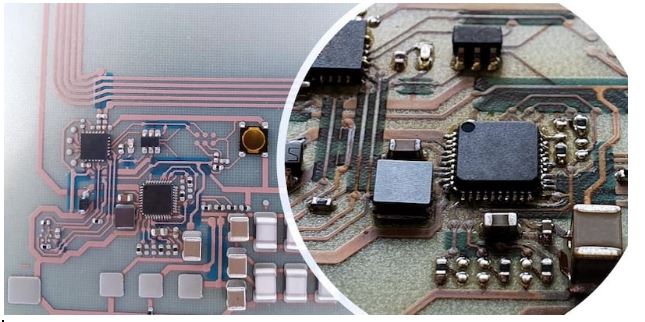

The world of electronics is constantly evolving, and with that evolution comes the need for PCB prototype services. PCBs or printed circuit boards are essential components that enable the proper functioning of electronic devices. Developing an efficient and reliable PCB is crucial to the success of any electronic product. This is where PCB prototype services come in – to provide cost-effective and efficient solutions for developing complex circuits from concept to final product.

A PCB prototype service involves designing, fabricating, and assembling prototypes to test functionality and optimize performance before moving on to full-scale production. This step is vital in the electronic product development process because it allows engineers to quickly and accurately test circuit designs on a small scale before committing to large-scale manufacturing. If you are in search of a reliable PCB prototype service, click the link: https://www.promaxpcb.expert/custom-prototype. PCB prototype services offer several benefits, including improved design quality, cost savings, reduced time to market, and increased reliability and durability.

Improved Design Quality: With PCB prototype services, engineers can test out their designs before committing to full-scale production runs. This allows them to quickly identify any potential issues with the circuit board layout and make adjustments as needed before going into full-scale production. Through prototyping, engineers can ensure their designs are as efficient and effective as possible when they reach the final production stages.

Cost Savings: By creating prototypes first, designers save on costs associated with producing large volumes of boards without knowing if there are any issues or flaws in the design beforehand. Additionally, prototyping eliminates costly rework or scrap costs if something needs to be changed after mass production has already begun, saving time and resources.

Reduced Time to Market: PCB prototype services can significantly reduce the time to market for electronic products. By providing quick and efficient solutions, engineers can test designs and make adjustments in real time, leading to faster product development.

Increased Reliability and Durability: Prototyping allows for design modifications before committing to large-scale manufacturing, leading to increased reliability and durability of the final product. Testing and optimizing performance before full-scale production can help identify any weak points in the design and ensure that the final product meets the required specifications.

PCB prototype services come in various types, including Through-Hole Prototyping, Surface Mount Technology (SMT) Prototyping, Mixed Technology Prototyping, Rigid Flexible Circuits, Multi-Layer Printed Circuit Boards (PCBs), High-Density Interconnect (HDI), Quick-Turnaround Prototyping, Low Volume Production, and Component Sourcing. These different types offer various benefits, such as more intricate designs, greater flexibility, and cost savings.

Through-Hole Prototyping involves drilling holes into a board and then mounting components on it through these holes. This allows for greater flexibility in terms of circuit design, as well as easier repairs if something goes wrong during the testing process. SMT Prototyping, on the other hand, uses surface mount technology to place each component directly onto the board without having to drill any holes. This allows for more intricate designs and is better suited for high-density circuits. Mixed Technology Prototyping combines both through-hole and surface mount technologies into one prototype.

Rigid Flexible Circuits are designed to be more versatile and can be bent or folded to fit into a variety of different electronic devices. Multi-Layer Printed Circuit Boards (PCBs) offer greater flexibility in terms of circuit design and can handle more complex circuits than single-layer boards. High-Density Interconnect (HDI) is a specialized technology that allows for more complex designs with smaller form factors, allowing for greater flexibility and cost savings. Quick-Turnaround Prototyping is a fast-paced and efficient service that allows for quick and effective solutions.