The Dangers of Working With Machinery

The ability to work with heavy machinery qualifies a person as skilled labor and often opens the door to higher income opportunities. However, earning more money in the production industry does not come without its risks. Machinery can malfunction at any time, especially if it’s not diligently maintained, properly staged, and used correctly.

Even small mistakes can result in devastating accidents that include loss of limb, blindness, severe burns, and death. Read on to learn more about the dangers of working with machinery, and to find out how companies are responsible for mitigating them.

Equipment Malfunctions

Heavy machinery is only as safe as it is well-maintained. Some companies continue using their machines day in and day out, without running the proper inspections, paying for professional tune-ups, or performing comprehensive in-house maintenance using qualified talent.

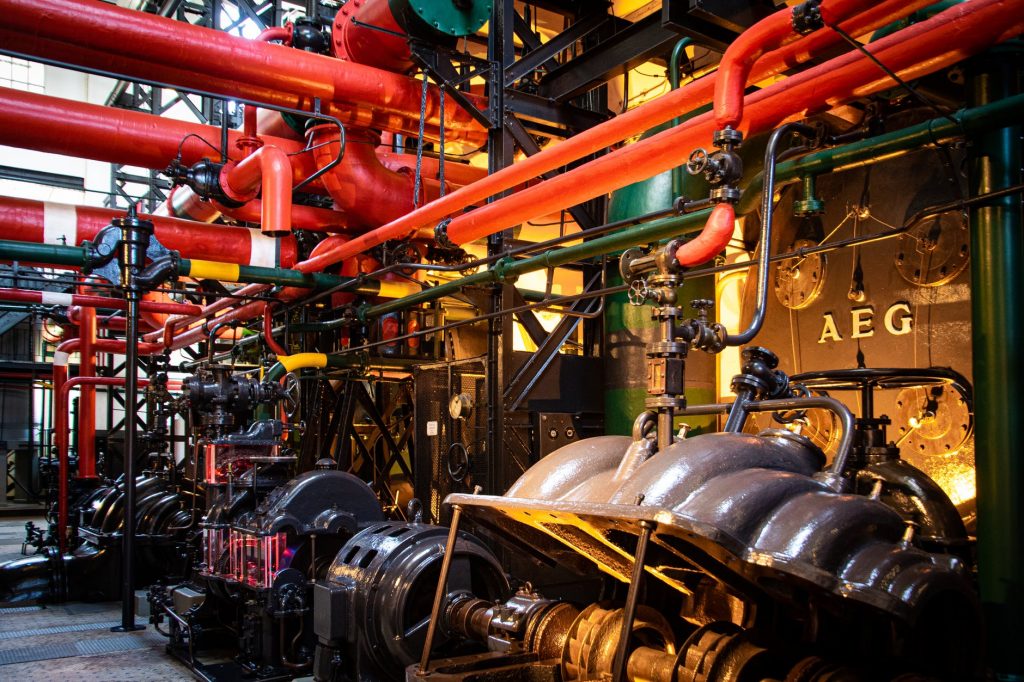

When equipment overheats, employees can suffer from steam burns that affect the face or the entire body, exposure to open flames, or even the release of highly corrosive chemicals.

While the dangers of working with machinery vary according to the work environment, the type of equipment being used, and its applications, poorly maintained and malfunctioning equipment can lead to a host of injuries including:

- Having the hands, hair, limbs, or other body parts become entangled in machine components

- Being dragged into moving machines

- Unexpected movement of machine components that result in impact injuries

- The release of high-temperature gases, chemicals, or water vapor

- Explosions

- Fire

While these are all risks that trained employees are well-aware of, certain forms of equipment maintenance must be scheduled and performed by higher-ranking team members, company owners, or third-party maintenance and compliance consultants.

In many work environments, awareness and even fear of having maintenance-related problems cause injuries is not enough to prompt fast action from the professionals who are empowered to deliver it. Fortunately, when businesses or their representatives are lax in these areas, they can be held liable for all resulting damages.

Insufficient Training

Just as dangerous as working with poorly maintained equipment is working with team members who lack adequate training, or working on heavy equipment without having the proper training yourself.

In addition to general, environment-specific safety training, companies must invest in equipment-specific training as well. This includes instructions on how to turn on, turn of, troubleshoot, and clean equipment and its various components without sustaining physical harm.

Before starting their work, all employees should be well-versed in the best practices for safe usage and the best practices for dealing with accidents and other unexpected events. This remains true whether businesses own their equipment outright or have simply rented heavy equipment for short-term use.

When using equipment rentals absent of employee training, companies must additionally hire seasoned, third-party operators who’ve received the necessary training and certification themselves.

Missing or Incorrect Personal Protective Equipment

Absent the right personal protective equipment (PPE), the risks of working with machinery become infinitely greater. In most industrial environments, basic PPE can include:

- Safety goggles or protective face shields

- Flame-resistant clothing when needed

- Hard hats

- Steel-toed boots

- Protective gloves

- Garments with reflective patches or stripes to notify others that dangerous equipment is being used

Some companies require their employees to cover the costs of their own PPE. However, even when workers are regularly reminded to wear PPE, and advised on the specific types of PPE to don for each activity, it is the job of shift supervisors to ensure that this gear is always being worn. Failure to do so can create a clear case for liability for businesses.

Moreover, shortcomings in this area can also result in penalties for non-compliance if reported to the proper authorities. You can learn more about the responsibilities of companies that use heavy equipment as part of their operations by visiting this source: https://www.sinklaw.com/south-carolina-personal-injury-lawyer/.

Improper Use of Equipment

Whether advised to do so by their shift supervisors or attempting to cut corners, some employees use heavy equipment in ways that it isn’t made for. This can include:

- Attempting to increase the rate of production

- Exceeding recommended load limits

- Bringing damaged equipment back into commission before it’s been inspected and repaired

- Using equipment in high-traffic areas

- Using equipment in applications that are not recommended by the equipment manufacturer

Misuse of equipment is often the result of insufficient experience and training. When equipment is improperly used, people can sustain deep cuts and sever injuries from sharp blades, impact injuries, falling injuries, and more. Improperly mounted or poorly staged equipment can also result in fatal crushing injuries, broken or shattered bones, and loss of limbs among many other things.

While the use of equipment greatly expedites production processes, it also exposes those who operate it to a substantial amount of risk. With experience, training, proper staging, and diligent maintenance, companies can help mitigate this risk. When businesses fall short in these areas, the consequences can be both devastating and long-lasting.

Pingback: 8 Fundamental Safety Rules That Should Never Be Compromised in Industrial Units - Night Helper